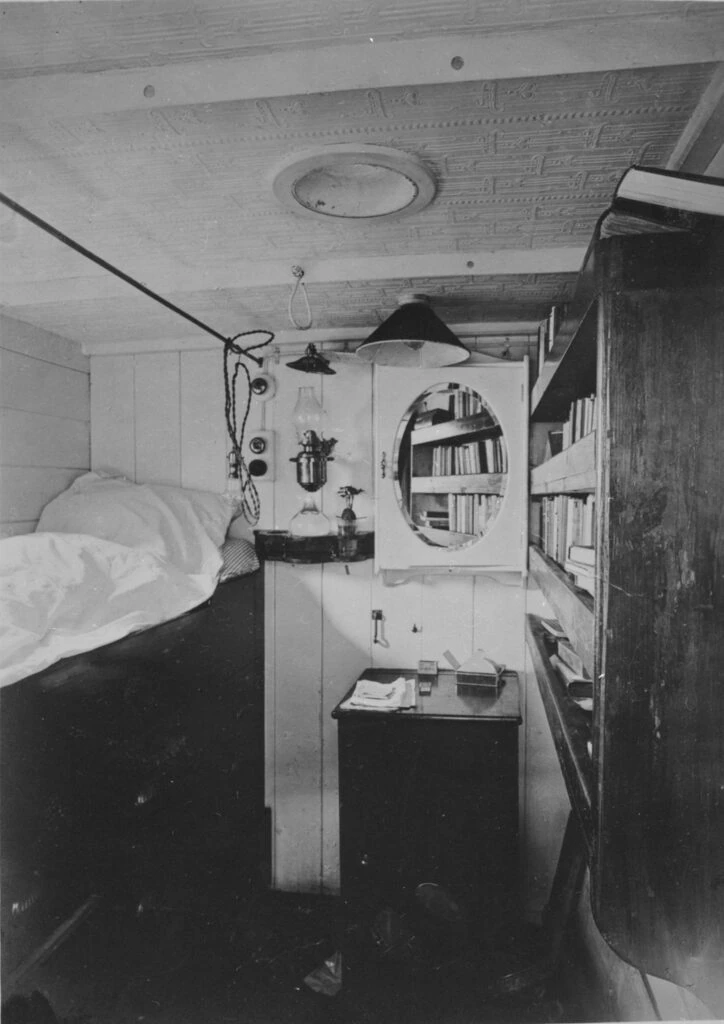

In 2016, Lincrusta Heritage Wallcoverings of Morecombe, Lancashire were approached to advise on the restoration of the sea cabin in which Antarctic explorer Ernest Shackleton died of a heart attack in 1922. Shackleton was on board his exploration ship Quest, which was anchored off South Georgia, en route to the Antarctic.

In 2016, Lincrusta Heritage Wallcoverings of Morecombe, Lancashire were approached to advise on the restoration of the sea cabin in which Antarctic explorer Ernest Shackleton died of a heart attack in 1922. Shackleton was on board his exploration ship Quest, which was anchored off South Georgia, en route to the Antarctic.

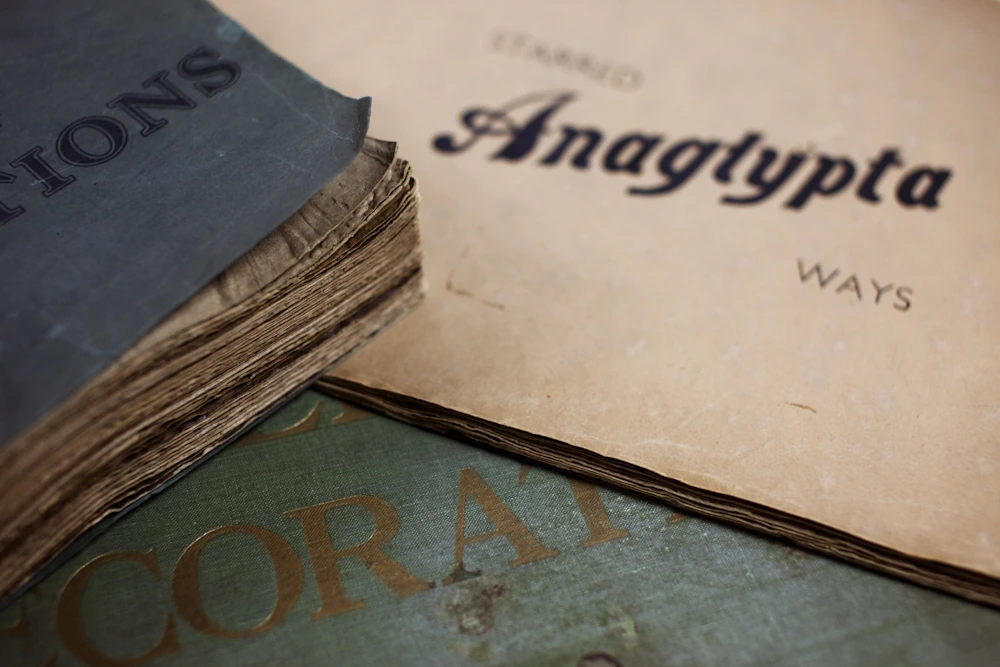

Lincrusta contacted us here at Anaglypta Restoration and with only a photo for reference, a matching mould was found within our historic archival materials. The design, manufactured by both Anaglypta and Lincrusta was pattern No. 619.

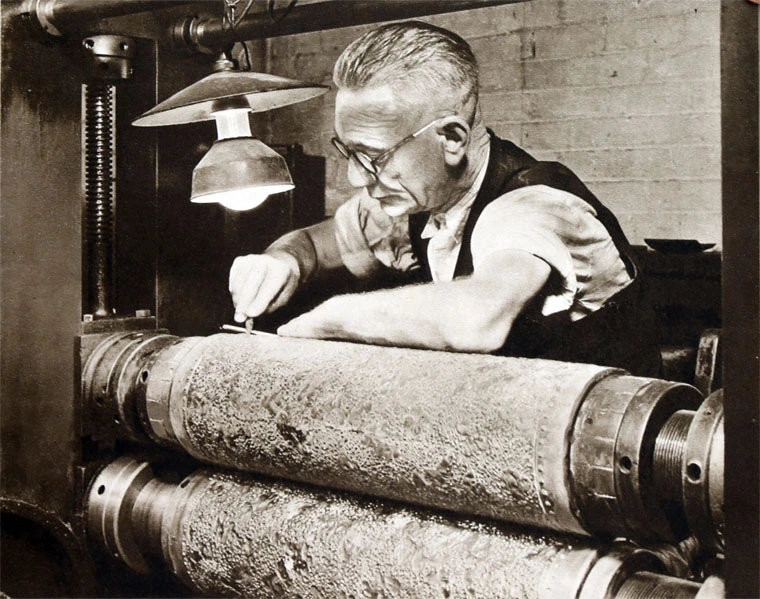

Our very own Michael Wilson was commissioned to manufacture a suitable mould that would be utilised to recreate and restore the design. The process required Michael to take our small duplicate mould, taken from an earlier project, and extend it to ensure it was a precise replica for the space. This was then carefully crafted, crated and shipped to Athy in Ireland, where it was used by the restoration team to restore this iconic space.

The process of restoring the interior was featured on the Irish TV channel RT1 on 2nd May 2022.